ULP series of ultra-low pressure aromatic polyamide compound membrane element newly developed by Vontron Membrane Technology Co., Ltd. can work under ultra low pressure to reach as high permeate flow and rejection same as regular low-pressure membrane element, and is applicable to desalination of surface water and underground water. It operates under approximately two thirds of the operating pressure of regular low-pressure composite membranes, which can decrease the investment costs for such relevant facilities as pumps, pipelines, and containers, etc. and the operating cost for the RO system, thus increasing the economic efficiency.

Applicable to desalination treatment of those water sources with NaCl lower than 2000 ppm, such as surface water, underground water, tap water and municipal water, ULP series membrane elements are mainly applicable to such as pure water, boiler water replenishment, foodstuff processing, and pharmaceutical production.

The LP (low pressure) series of aromatic polyamide compound membrane element developed by Vontron Membrane Technology Co., Ltd. has the properties of low-pressure operation, high permeate flow and excellent desalination and is applicable to desalination of brackish water. Besides, it is particularly applicable to fabrication of high-purity water for electronic industry and electric power industry owing to its excellent performance in removing soluble salts, TOC, SiO2, etc.

Being suitable for desalting such water sources as surface water (NaCl ≤10000ppm), underground water, tap water and municipal water, etc., LP series is mainly applicable to treatment of various industrial water such as industrial-purpose pure water, boiler water replenishment in power plants, and can be also applied to such brackish water applications, such as treatment of high-concentration saline waste water and production of beverage-purpose water.

Domestic Water Treatment

Commercial Water Treatment

Industrial Water Treatment

| Model | Active Membrane Area ft2(m2) |

Average Permeate GPD(m3 /d) |

Stable Rejection Rate % |

Min. Rejection Rate % |

| LP22-8040 | 400(37.2) | 10500(39.7) | 99.5 | 99.3 |

| Testing Conditions |

Testing Pressure Testing Solution Temperature Concentration of Testing Solution (NaCl) pH value of Testing Solution Recovery Rate of Single Element |

225 psi (1.55Mpa) 25˚C 2000ppm 7.5 15% |

||

| Operation Limits & Conditions |

Max. Working Pressure Max. Temperature of Feed water Max. Volume of Feed water Max. Feed water SDI15 pH Range of Feed water during Continuous Operation pH Range of Feed Water during Chemical Cleaning Residual Chlorine Concentration of Feed Water Max. Pressure Drop of Single Membrane Element Max. Pressure Drop of Single Pressure Vessel with Six RO Membranes |

600psi(4.14Mpa) 45˚C 75gpm (173/h) 5 2~11 1~13 <0.1ppm 15psi (0.1Mpa) 50psi (034Mpa) |

||

| Model | Active Membrane Area ft2(m2) |

Average Permeate GPD(m3 /d) |

Stable Rejection Rate % |

Min. Rejection Rate % |

| ULP22-8040 | 400(37.2) | 12100(45.7) | 99.0 | 98.5 |

| Testing Conditions |

Testing Pressure Testing Solution Temperature Concentration of Testing Solution (NaCl) pH value of Testing Solution Recovery Rate of Single Element |

150 psi (1.55Mpa) 25˚C 1500ppm 7.5 15% |

||

| Operation Limits & Conditions |

Max. Working Pressure Max. Temperature of Feed water Max. Volume of Feed water Max. Feed water SDI15 pH Range of Feed water during Continuous Operation pH Range of Feed Water during Chemical Cleaning Residual Chlorine Concentration of Feed Water Max. Pressure Drop of Single Membrane Element Max. Pressure Drop of Single Pressure Vessel with Six RO Membranes |

600psi(4.14Mpa) 45˚C 75gpm (173/h) 5 3~10 2~12 <0.1ppm 15psi (0.1Mpa) 50psi (034Mpa) |

||

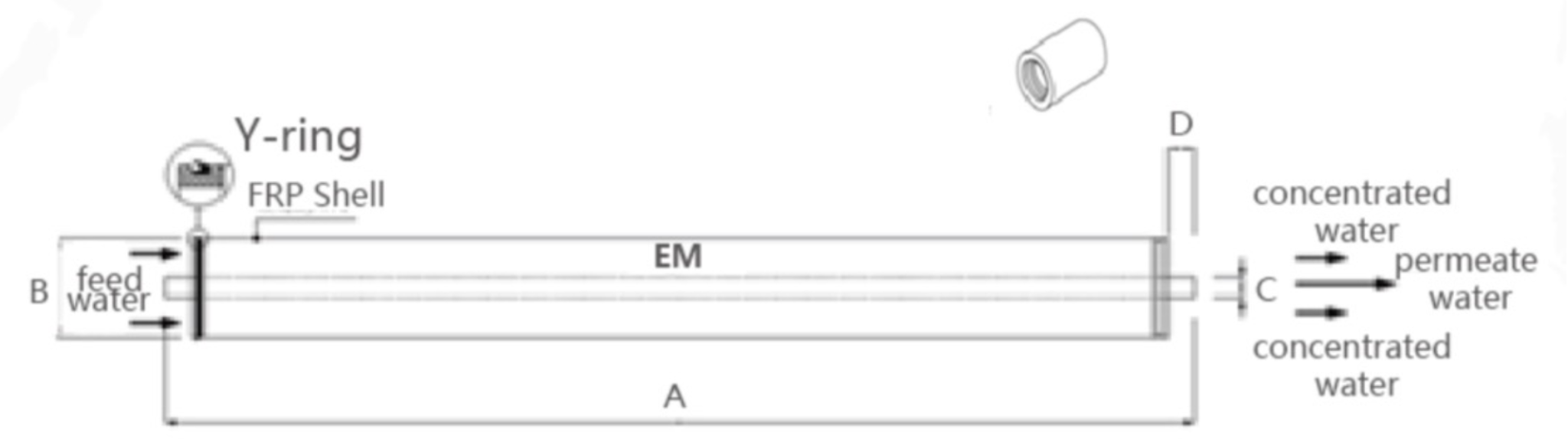

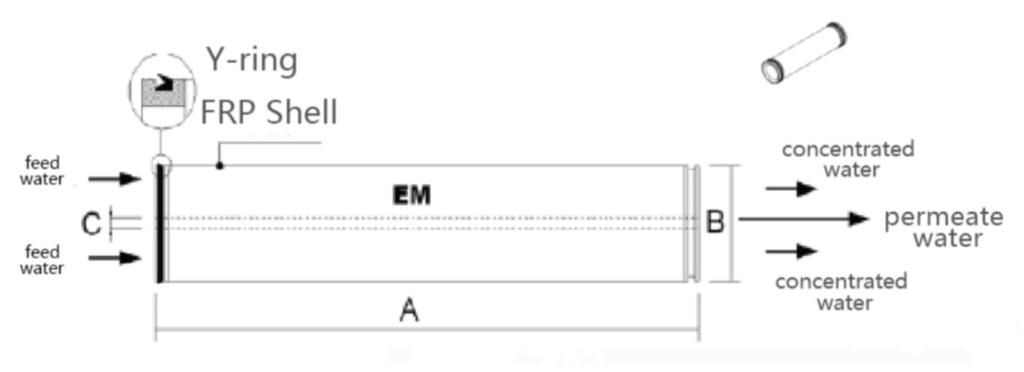

(A)

(B)

Below is a video that explains how an RO membrane is made

https://youtu.be/c640QM5Ccyw

Below is a video that explains how an RO membrane works

https://youtu.be/jOYZWPhjUI4

| Title |

Default Title |

|---|

Your Custom field here